Optiflux Orientation Process – A Patented Breakthrough in PVC-O Technology

OTIPL, formerly Optiflux Pipes Industries, has been a pioneer in PVC-O pipe manufacturing since 2013. Certified by BIS and ISO 16422, it ensures high-quality standards with a strong production capacity of 8000 MT per annum. Approved by key state water authorities and trusted internationally, including a successful project in South Africa, OTIPL is a reliable name in advanced pipe solutions.

At Optiflux, we have developed and patented an advanced molecular orientation process that transforms conventional PVC into PVC-O (Molecularly Oriented PVC) — a material engineered for maximum strength, efficiency, and durability.

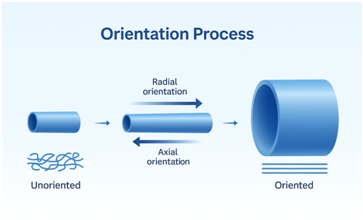

The Process

Through our proprietary Molecular Orientation technology, the molecular chains in the pipe wall are precisely oriented in both axial and circumferential directions.

This unique alignment enhances the polymer structure, enabling Optiflux to produce PVC-O pipes of Class 500 (MRS 50) — the highest performance category defined under international standards

Layered Structure of PVC-O Pipe – Engineered by Optiflux Technology

Optiflux PVC-O pipes are designed with a precision-oriented, multi-layered structure that delivers unmatched strength, flexibility, and long-term performance

Each layer in the pipe is engineered through Optiflux’s patented molecular orientation process, ensuring consistent material quality and superior mechanical properties.

High Strength Class 500

Orientation increases the tensile and hoop strength of the material, achieving Class 500 (MRS 50) performance — nearly double the strength of standard PVC.

Lightweight & Flexible

Delivers superior mechanical strength with 30–40% less weight, ensuring easy handling and reduced installation costs

Enhanced Impact Resistance

The oriented molecular structure provides exceptional resistance to shocks, ground movement, and water hammer effects

Optiflux – Engineering Tomorrow’s Water Infrastructure

Optiflux is India’s first startup pioneering PVC-O pipe technology, offering advanced manufacturing systems and high-performance pipes built for strength, efficiency, and sustainability.

With patented technology and in-house equipment design, Optiflux is redefining how the world sees PVC-O innovation — Made in India, for the world.

Avas Digital Agency

Phasellus tempus diam et est tristique eget aliquam quam vestibulum onec congue enim volutpat sagittis nunc non consectetur exers.

- All

- Bootstrap

- PHP

- Redux

- Responsive

- WooCommerce

- WordPress

Portfolio One

Lorem ipsum dolor sit

Portfolio One

Suspendisse potenti Phasellus euismod libero in neque molestie et elementum libero maximus. Etiam in enim vestibulum suscipit sem quis molestie nibh. Donec ac lacus nec diam gravida pellentesque. Morbi viverra facilisis massa a ullamcorper. Vivamus egestas tincidunt faucibus. Nulla tristique urna id lacinia egestas sapien arcu convallis velit id porta turpis velit molestie enim. In sagittis purus eget semper ullamcorper nisi lorem condimentum tellus vitae semper quam enim vitae justo. Vestibulum vulputate posuere nunc…

Portfolio Two

Lorem ipsum dolor sit

Portfolio Two

Suspendisse potenti Phasellus euismod libero in neque molestie et elementum libero maximus. Etiam in enim vestibulum suscipit sem quis molestie nibh. Donec ac lacus nec diam gravida pellentesque. Morbi viverra facilisis massa a ullamcorper. Vivamus egestas tincidunt faucibus. Nulla tristique urna id lacinia egestas sapien arcu convallis velit id porta turpis velit molestie enim. In sagittis purus eget semper ullamcorper nisi lorem condimentum tellus vitae semper quam enim vitae justo. Vestibulum vulputate posuere nunc…

Portfolio Three

Lorem ipsum dolor sit

Portfolio Three

Suspendisse potenti Phasellus euismod libero in neque molestie et elementum libero maximus. Etiam in enim vestibulum suscipit sem quis molestie nibh. Donec ac lacus nec diam gravida pellentesque. Morbi viverra facilisis massa a ullamcorper. Vivamus egestas tincidunt faucibus. Nulla tristique urna id lacinia egestas sapien arcu convallis velit id porta turpis velit molestie enim. In sagittis purus eget semper ullamcorper nisi lorem condimentum tellus vitae semper quam enim vitae justo. Vestibulum vulputate posuere nunc…

Portfolio Four

Lorem ipsum dolor sit

Portfolio Four

Suspendisse potenti Phasellus euismod libero in neque molestie et elementum libero maximus. Etiam in enim vestibulum suscipit sem quis molestie nibh. Donec ac lacus nec diam gravida pellentesque. Morbi viverra facilisis massa a ullamcorper. Vivamus egestas tincidunt faucibus. Nulla tristique urna id lacinia egestas sapien arcu convallis velit id porta turpis velit molestie enim. In sagittis purus eget semper ullamcorper nisi lorem condimentum tellus vitae semper quam enim vitae justo. Vestibulum vulputate posuere nunc…

Portfolio Five

Lorem ipsum dolor sit

Portfolio Five

Suspendisse potenti Phasellus euismod libero in neque molestie et elementum libero maximus. Etiam in enim vestibulum suscipit sem quis molestie nibh. Donec ac lacus nec diam gravida pellentesque. Morbi viverra facilisis massa a ullamcorper. Vivamus egestas tincidunt faucibus. Nulla tristique urna id lacinia egestas sapien arcu convallis velit id porta turpis velit molestie enim. In sagittis purus eget semper ullamcorper nisi lorem condimentum tellus vitae semper quam enim vitae justo. Vestibulum vulputate posuere nunc…

Portfolio Six

Lorem ipsum dolor sit

Portfolio Six

Suspendisse potenti Phasellus euismod libero in neque molestie et elementum libero maximus. Etiam in enim vestibulum suscipit sem quis molestie nibh. Donec ac lacus nec diam gravida pellentesque. Morbi viverra facilisis massa a ullamcorper. Vivamus egestas tincidunt faucibus. Nulla tristique urna id lacinia egestas sapien arcu convallis velit id porta turpis velit molestie enim. In sagittis purus eget semper ullamcorper nisi lorem condimentum tellus vitae semper quam enim vitae justo. Vestibulum vulputate posuere nunc…

Portfolio Seven

Lorem ipsum dolor sit

Portfolio Seven

Suspendisse potenti Phasellus euismod libero in neque molestie et elementum libero maximus. Etiam in enim vestibulum suscipit sem quis molestie nibh. Donec ac lacus nec diam gravida pellentesque. Morbi viverra facilisis massa a ullamcorper. Vivamus egestas tincidunt faucibus. Nulla tristique urna id lacinia egestas sapien arcu convallis velit id porta turpis velit molestie enim. In sagittis purus eget semper ullamcorper nisi lorem condimentum tellus vitae semper quam enim vitae justo. Vestibulum vulputate posuere nunc…

Portfolio Eight

Lorem ipsum dolor sit

Portfolio Eight

Suspendisse potenti Phasellus euismod libero in neque molestie et elementum libero maximus. Etiam in enim vestibulum suscipit sem quis molestie nibh. Donec ac lacus nec diam gravida pellentesque. Morbi viverra facilisis massa a ullamcorper. Vivamus egestas tincidunt faucibus. Nulla tristique urna id lacinia egestas sapien arcu convallis velit id porta turpis velit molestie enim. In sagittis purus eget semper ullamcorper nisi lorem condimentum tellus vitae semper quam enim vitae justo. Vestibulum vulputate posuere nunc…

Website Design Services

Best Marketing Services

Publishing Media Giants

What We Do

Optiflux develops and supplies

- Patented PVC-O Manufacturing Technology

- High-Strength Class 500 (MRS 50) Pipes

- Complete Solutions for PVC-O production

Optiflux PVC-O Manufacturing Equipment Lineup

Optiflux offers a range of custom-engineered machines for producing Class 500 (MRS 50) PVC-O pipes — designed for high output, consistent quality, and efficient energy use.

Each model is optimized for specific pipe diameters and production capacities, ensuring flexibility for small, medium, and large-scale manufacturers.

|

Model

|

Pipe Size

|

Production Capacity per Annum

|

|---|---|---|

|

OPTECH 200

|

110 - 200

|

1600 MT

|

|

OPTECH 400

|

110 - 400

|

3000 MT

|

|

OPTECH 630

|

250 - 630

|

4500 MT

|

Custom Engineering by Optiflux

Optiflux also offers tailor-made systems for specific customer requirements, pipe sizes, or local standards.

Our expert team provides end-to-end support — from design, installation, and commissioning to operator training

What is PVC-O?

Bi-Axially Oriented Polyvinyl Chloride

Definition & Process

PVC-O stands for Bi-axially Oriented PVC, A pre-form PVC pipe of half the diameter is first made via extrusion, then undergoes orientation which inflates and aligns PVC molecules into a stronger structure.

Molecular Orientation

PVC molecules are stretched and aligned under controlled heat and pressure, creating a layered polymer structure with enhanced properties.

Resulting Strength

This orientation process gives PVC-O pipes superior mechanical strength, flexibility, and resistance to cracking under pressure or impact.

compliance with standards world wide

Manufactured in Class 500 as per IS 16647:2017 for sizes ranging from 110 mm to 1200 mm with pressure ratings of PN12.5 to PN25.

PVC-O vs Traditional Pipe Materials

Strength-to-Weight Ratio

PVC-O pipes offer high mechanical strength at a fraction the weight of metal or PVC-U pipes, improving handling and logistics.

Hydraulic Efficiency

Smooth inner surfaces in PVC-O reduce friction losses, maintaining consistent flow and minimizing energy usage over time.

Crack Resistance

PVC-O resists rapid crack propagation thanks to its layered molecular structure; PVC-U and metals are more prone to fracture.

Installation & Cost Efficiency

Lighter weight and flexibility make PVC-O easier and cheaper to install, with lower overall lifecycle costs than metal or rigid PVC.

Advanced Strength & Reliable Manufacturing

OPTIFLUX™ High-Strength Oriented PVC (PVC-O) pipes utilize molecular orientation technology to transform PVC into a highly ordered structure, delivering superior strength, pressure resistance, and long-term durability. Manufactured in strict compliance with IS 16647:2017 and ISO 16422:2014, these pipes ensure consistent quality, reliability, and optimal performance for water supply and pressurized applications.

Molecular Orientation Technology

Transforms PVC’s random molecular structure into a highly ordered, layered form for superior performance.

Enhanced Strength & Pressure Capacity

Pipes can withstand higher pressures and impacts, ensuring long-term reliability.

Greater Flexibility

Improved adaptability makes pipes ideal for diverse applications, from water supply to irrigation.

Corrosion & Chemical Resistance

Oriented PVC structure provides excellent resistance to corrosion, chemicals, and environmental degradation, ensuring durability in varied conditions.

Automated Precision

Fully automated production ensures consistency, accuracy, and reduced human error.

Low Maintenance & Efficiency

Streamlined process reduces upkeep, while optimizing efficiency and reliability.

Energy & Cost Savings

Lower power consumption translates into reduced operational costs and faster ROI.

Certified Quality

Adheres to BIS and ISO standards, guaranteeing dependable, long-lasting performance.

Praveen Parihar

Amit Borana

James Bond

Sara Karles

Lorem ipsum dolor sit amet conse ctetur adipiscing elit sed do eiusmod tempor incididunt ut labore et dolore.

Ut enim ad minim veniam quis nostrud exercitation ullamco laboris nisi ut aliquip exea commodo consequat.

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Suspendisse potenti Phasellus euismod libero in neque molestie et mentum libero maximus. Etiam in enim vestibulum.

Testimonial

Lorem ipsum dolor sit amet consectetur adipiscing elit sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

John Doe

Ut enim ad minim veniam quis nostrud exercitation ullamco laboris nisi ut aliquip exea commodo consequat.

Sharon Brinson

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Felix Mercer

Recent News

Etiam imperdiet imperdiet orciunc nec neque leo dolor tempus non auctor hendrerit quis nisi ligula sapien tincidunt non euismod vitae mpus diam et est tristique eget aliquam quam vestibulum.

Why PVC-O Pipes Are the Future of

The need for effective and efficient water infrastructure is rapidly rising in the Indian market. With the increasing rate of urbanization, agricultural development, and the great need for efficient

Challenges Faced by PVC-O Pipe Class

The Indian piping sector has been experiencing constant growth due to development in infrastructure, water supply schemes, and irrigation requirements. In the sector of advanced piping technology, PVC-O (Biaxially

PVCO Pipe Manufacturers in India:

PVCO pipe production has also been established at the core of the plumbing and irrigation requirements and the industrial needs of India. With the rising need for robust and

Difference Between Offline and Online

PVC-O pipes are one of the most favoured options in modern water infrastructure due to their high strength, light weight, and long life. With industries and utilities moving to

A Buyer’s Guide to Selecting OPVC Pipe

Among the current available options, OPVC Pipe Class 500 has emerged as probably the most resilient, effectual, and cost-effective piping method for large infrastructure systems such as water supply,

Why OPVC Pipe Class 500 Is Becoming

The ever-increasing urban population and industrialization have taken a big toll on the water supply infrastructure in India. With the expansion of cities and the increasing demand for clean

What are the advantages of PVC-O /

Material choice for piping is playing a very important role in modern infrastructure projects to ensure efficiency and durability for its long-term performance. Amongst the many options available, the

Understanding Class 500 Standards in

In today’s ever-evolving field of manufacturing, nothing is more crucial than ensuring quality standards and smoothness in operations. Offline process machines are indispensable in several industrial applications, and going