Features

Know about our revolutionary technology

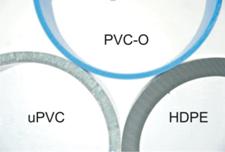

Some of the advantages of OPTIFLUX High Strength Oriented PVC Pipes over uPVC, HDPE and Ductile Iron pipes are as follows:-

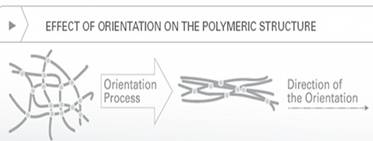

- High-Tech Manufacturing Mechanism: OPTIFLUX PVC-O pipes are manufactured using a revolutionary new molecular orientation process. This ultra high-tech process uses the pre-formed PVC pipe with double the wall thickness and half the diameter of the pipe to be manufactured and expand it under precise and homogenous distribution of temperature and pressure to orient the PVC molecules both in the axial and circumferential directions (biaxial orientation). The result is a pipe with enhanced toughness and flexibility. While this cutting-edge manufacturing technology is expensive; it results in the strongest, toughest and most consistent high-quality pipes available in the market today.

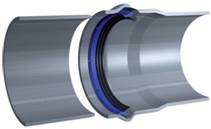

- High Quality Integrated Sealing System: OPTIFLUX PVC-O Pipes are supplied with company fitted anti-termite EPDM rubber sealing rings. The unique ring design comprises of rubber sealing element bonded to plastic retaining element which holds the seal securely in position during transport and pipe assembly. This combined lip and compression seal is positioned and locked inside the socket bell at the time of manufacturing. The integrated ring fitting mechanism ensures that the ring is not displaced from its setting during installation which eliminates the chances of leakage.

- Low Embodied Energy: Embodied energy is defined as the non-renewable energy consumed in all the activities associated to the pipe’s lifecycle i.e. direct energy plus indirect energy. This lifecycle includes raw material extraction, manufacture, installation and other supporting functions, such as transport. It requires minimal energy to manufacture PVC-O pipe as compared to Ductile Iron, uPVC and HDPE pipes thus giving it less than half the carbon footprint of Ductile Iron pipes.

- Low Cost: PVC-O pipes are approximately 30% - 50% cheaper than Ductile Iron pipes whilst maintaining the same pressure handling capabilities as Ductile Iron pipes and better physical and mechanical properties like strength and ductility. Looking at the current market prices, the cost of PVC-O pipe is double than the cost of uPVC pipes and half the cost of Ductile Iron pipe for the same size and pressure class thus saving the cost of water supply projects.

- No Extra Filler Content: PVC-O pipes are made up of PVC resin, some chemicals & additives and limited amount of filler (up to 4%). There is no chance of high filler content which makes the pipe weak and reduces life. The perform pipe must be flawless in order to survive the expansion process, the process acts as its own quality control. As this pipe is manufactured by expansion at precise temperature and pressure conditions, if quantity of filler is increased then there is no technical possibility of pipe being manufactured in proper shape and size. The cutting edge manufacturing technology guarantees no extra filler content, thus ensuring best quality PVC-O pipes.

- Environment Friendly: Co-operating for sustainable development is an issue which concerns everyone. PVC-O pipes emit the least amount of CO2 in every link of its lifecycle chain, from the production of the raw material to the manufacturing of the tubes, their installation, and during their useful lives when they transport fluids thus giving low carbon footprints. OPTIFLUX PVC-O has no additives containing toxic heavy metal compounds, such as lead based materials. This actively prevents more of these compounds entering the environment. PVC-O pies are most eco-friendly pipes available in the market.

- 100% Recyclable: PVC-O pipes are 100% recyclable at the end of their service life. PVC-O pipes can utilize re-processable PVC material from the manufacturer’s own process as permitted by the manufacturing standard ISO 16422:2006. No re-processable material obtained from the external sources can be used (5.2 Re-work Material, ISO 16422:2006). They can also be ground and re-processed for reuse in the manufacture of other plastic products without losing any of its properties.

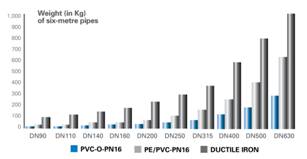

- Low Weight: PVC-O pipes are around 6 to 12 times lighter per meter size wise as compared to Ductile Iron pipe. This makes them easy and cheaper for handling and transportation. Low

installation costs results in huge savings on over all projects costs.

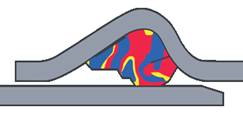

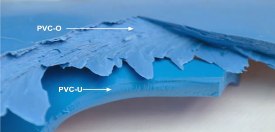

- Unbeatable Impact Resistance: The process of molecular orientation give PVC-O pipes layered structure which results in higher impact strength as compared to Ductile Iron, uPVC and HDPE pipes. PVC-O pipes are virtually impossible to destroy by impact.

- Crush Resistant: The molecular orientation of PVC-O pipes allows it to withstand extreme compression and be crushed flat without cracking, splitting or failing.

- Increased Hydraulic Capacity: PVC-O pipes have smooth bore which stays smooth over long years of service which gives low flow resistance with no loss in carrying capacity. It’s co-efficient of flow C=150(Hazen & Williams) the best available in common use water systems. Also it has less wall thickness as compared to uPVC and Ductile Iron pipes of the same pressure rating which leads to larger Inner Diameter and thus higher flow capacity. This capacity often allows savings in pumping costs to a great extent.

- Maximum Flexibility: Due to the excellent elasticity of PVC-O pipes they can bear deformation up to 100% of their internal diameter. When crushed or in the event of a mechanical accident, it immediately goes to its original shape thus eliminating the risk of potential breakage by soil subsidence or sharp edges on rock or machinery. Its increased flexibility means a reduced bending radius that allows it to fit around gradual curves.

- Crack Resistant: PVC-O pipes are crack resistant as the layered structure of PVC-O pipes do not allows the crack to propagate over the subsequent layers thus resisting the pipe from cracking. In case of uPVC pipes due to the amorphous structure the pipe gets cracked easily.

- Easy Handling & Transportation and Lower installation Cost: Due to lighter weight of PVC-O pipes as compared to Ductile Iron, HDPE and uPVC pipe it requires no heavy, fuel consuming equipment to transport or install, while reducing labor costs due to easy lifting. Most sizes can be handled manually without any mechanical assistance, so there is no need for costly installation equipment which results in faster installation and saving more in cost per foot installed.

- Better pressure Handling & Strength: The allowable working pressure of uPVC Class-3 pipe normally used in PHED is 6 kg/cm2 where as the working pressure of Ductile Iron K7 and K9 pipe is 16kg/cm2 and 25 kg/cm2 respectively. Against this the working pressure of PVC-O pipe is 16 kg/cm2 and 25 kg/cm2 . It is clear that the allowable working pressure for PVC-O pipe is equivalent to Ductile Iron pipe for most of the pipe sizes. The ultimate tensile strength of PVC-O pipe is two times the tensile strength of uPVC pipe and is equivalent to that of Ductile Iron pipe.

- Easy Jointing Mechanism: OPTIFLUX PVC-O pipes use standard rubber ring jointing mechanism. The EPDM rubber sealing ring is positioned and locked inside the socket bell at the time of manufacturing thus avoids displacement from its setting or movement when installation is taking place avoiding the chances of leakage. No special training is required to install the pipes as the pipes are easy to join in the same way as in the case of uPVC pipes. The joints are 100 percent watertight and are guaranteed not to displace once the pipes have been installed. Pipe jointing is faster and there is no need for welded unions.

- Lower Pumping Cost: Due to smooth surface and larger inner diameter of PVC-O pipes the pumping cost is about 20% lower than the Ductile Iron pipes. This ultimately results in saving of electricity consumption thus huge saving of Government funds.

- Excellent Response to Water Hammers: Water hammers can place greater pressure on a pipe’s working pressure and lead to leakage, particularly when the pipe has already been damaged by impacts or corrosion. PVC-O pipes offer lower celerity than other piping systems (four times less than ductile iron pipes), which means less water hammers caused by sudden variations in water volume and pressure. This reduces and almost eliminates the possibility of breakage during opening and closing of the valves and when pumping gets under way, protecting every component of the network.

- Chemically Inert & Corrosion Resistant: PVC-O pipes are chemically inert towards almost all substance found in nature such as micro and macro organisms which results in longevity. PVC-O pipes are unaffected by electrolytic or galvanic corrosion and sedimentation unlike iron pipe. Because it is non-metallic, the pipe does not lose strength due to either potable water corrosion or external galvanic soil conditions. There is no need for tuberculation, costly lining, wrapping, coating or cathodic protection. The quality of fluid that circulates in PVC-O pipe will always remain unaltered as the pipe never suffers corrosion or migrations within the pipes or on their coatings.

- Optimal Use of Water Resources: Water supply infrastructure networks that used traditional materials are currently registering a leakage rate of up to 25% of channeled water and the latter’s chemical deterioration means that some water conduits are currently being replaced despite having being laid only a few years ago. Infrastructures created with PVC-O pipes are a tool for managing water resources for generations to come.

- World Wide Acceptance: PVC-O pipes are accepted internationally for use in potable water supply networks. Various standards have been developed in different countries over the product in order to maintain the quality of the product. This shows that the pipe has been internationally accepted by several developed countries and has been brought to use long ago. Standards for PVC-O have been developed in countries like Spain, France, Australia, New Zealand, United States, Brazil, Columbia, Canada, and United Kingdom etc. Some International Standardization agencies like ISO (International Standards Organization), AWWA (American Water Works Association) have also developed codes to standardize this product. The rising worldwide demand of PVC-O Pipes leads to the introduction and continuous development of international standards to ensure the quality of the product. Countries which have not developed manufacturing standard for this product are manufacturing the pipe on the basis of ISO (ISO 16422:2006). Case studies showing the application of PVC-O Pipes have been provided here with.